Understanding the behavior of materials under varying temperatures is crucial in numerous engineering applications. Linear expansion of metals, a phenomenon explored extensively by institutions like the National Institute of Standards and Technology (NIST), dictates how metallic structures react to thermal changes. The coefficient of thermal expansion, a material property, quantifies the extent of this dimensional change. Furthermore, bridge construction represents a prime example where accounting for linear expansion is paramount to prevent structural failures. Thus, a strong grasp of this concept is key to unlocking secrets about how metallic materials behave.

Image taken from the YouTube channel The Organic Chemistry Tutor , from the video titled Linear Expansion of Solids, Volume Contraction of Liquids, Thermal Physics Problems .

The behavior of materials under varying temperatures is a cornerstone of engineering and material science. Among these behaviors, linear expansion stands out as a fundamental property, particularly when dealing with metals. This section serves as an introduction to this vital concept, exploring its definition, its place within the broader phenomenon of thermal expansion, and its critical role in various applications.

Defining Linear Expansion

Linear expansion refers to the tendency of solid materials to change in length in response to changes in temperature. When a metal is heated, its particles move more vigorously, leading to an increase in the average separation between them.

Consequently, the object expands. Conversely, cooling a metal causes it to contract as its particles slow down and move closer together.

This change in length is linear because it primarily affects one dimension of the object – its length – although width and thickness also change, these are often negligible compared to the change in length.

Thermal Expansion: The Broader Context

Linear expansion is a specific type of thermal expansion, which encompasses the changes in volume, area, and length of a substance in response to temperature fluctuations.

Thermal expansion is a physical property of materials that describes how their size changes with temperature. It’s a broader term that includes:

- Volumetric expansion (change in volume)

- Area expansion (change in area)

- Linear expansion (change in length).

While linear expansion focuses on the change in one dimension, thermal expansion provides a more holistic view of how a material responds to temperature variations. Understanding thermal expansion, in general, helps contextualize the importance of linear expansion in specific scenarios where length changes are the primary concern.

The Importance of Linear Expansion in Engineering and Construction

The understanding and management of linear expansion are paramount in engineering and construction. Failure to account for this phenomenon can lead to catastrophic structural failures.

For example, bridges and buildings are subject to significant temperature variations throughout the year. If the expansion and contraction of the materials used in these structures are not properly accommodated, stresses can build up, leading to cracks, buckling, or even collapse.

Similarly, in the design of railway tracks, pipelines, and other infrastructure, engineers must carefully consider the linear expansion properties of the materials to ensure the safety and longevity of these structures.

Common Metals and Their Expansion

Many metals exhibit linear expansion, each with its unique coefficient of expansion. Some common examples include:

- Steel: Widely used in construction and engineering due to its strength and relatively moderate expansion.

- Aluminum: Known for its lightweight and high thermal conductivity, aluminum experiences more expansion than steel.

- Copper: Commonly used in electrical wiring and plumbing, copper has a moderate expansion coefficient.

- Iron: A fundamental component of steel, iron’s expansion characteristics are crucial in understanding the behavior of steel structures.

The specific linear expansion properties of these and other metals are essential considerations in material selection for various engineering applications. The following sections will further explore how these properties are characterized and utilized in real-world scenarios.

Key Concepts in Linear Expansion

Having established what linear expansion is and where it fits within the bigger picture of thermal behavior, it’s time to explore the underlying mechanisms that drive this phenomenon. This delves into the core principles that govern how much a metal will expand for a given temperature change, and why heat is the essential ingredient.

Understanding the Coefficient of Linear Expansion

The coefficient of linear expansion is the keystone for quantifying and predicting a material’s response to temperature fluctuations. It essentially provides a metal’s "expansion fingerprint."

Defining the Coefficient and its Units

The coefficient of linear expansion, often represented by the Greek letter alpha (α), is defined as the change in length per unit of original length for each degree Celsius (or Fahrenheit) change in temperature.

Its units are typically expressed as 1/°C or 1/°F.

A higher coefficient indicates that a material will expand more for a given temperature change. Conversely, a lower coefficient signifies less expansion.

Variation Among Different Metals

A critical aspect of the coefficient of linear expansion is that it is not universal. Different metals possess distinct coefficients, reflecting variations in their atomic structure and bonding forces.

For example, aluminum has a significantly higher coefficient of linear expansion than steel. This means that, for the same temperature increase, an aluminum bar will expand considerably more than a steel bar of the same original length.

This inherent variability is a crucial consideration in engineering design.

The Relationship Between Temperature Change and Linear Expansion

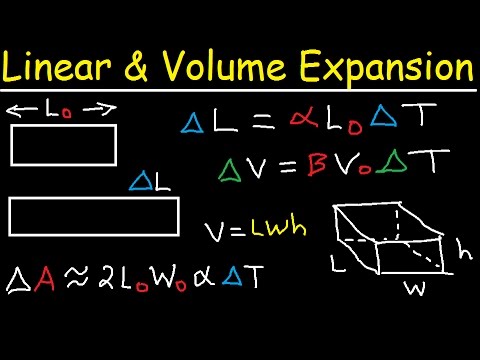

The extent of linear expansion is directly proportional to the temperature change experienced by the metal. This relationship is expressed mathematically as:

ΔL = α L₀ ΔT

Where:

- ΔL is the change in length.

- α is the coefficient of linear expansion.

- L₀ is the original length.

- ΔT is the change in temperature.

This formula underscores a critical point: the greater the temperature change, the greater the linear expansion. Similarly, a larger original length will result in a larger absolute expansion for the same temperature change.

The Role of Heat in Causing Thermal Expansion

Heat, the transfer of thermal energy, is the catalyst for thermal expansion. When a metal is heated, the energy is transferred to its atoms.

These atoms, which are already in constant vibration, begin to vibrate more vigorously.

This increased atomic motion leads to a greater average separation between the atoms, resulting in an overall increase in the material’s dimensions.

The stronger the heat, the more vigorous the vibration, and, therefore, the greater the expansion. Conversely, removing heat (cooling) reduces atomic motion and causes contraction.

Having established that a material’s coefficient dictates its expansion behavior with changing temperature, it’s natural to question how this plays out in the real world. Different metals, with their varying atomic structures and bonding characteristics, exhibit a wide range of expansion coefficients. This inherent diversity is not merely a scientific curiosity; it directly impacts material selection and design choices across countless engineering applications.

Metals and Their Expansion Properties

The linear expansion of metals isn’t just an academic concept. It’s a practical reality that engineers and designers must consider daily. This section dives into specific examples, comparing the expansion properties of common metals and exploring why certain metals are favored in particular applications due to their unique expansion behaviors.

Comparing Expansion Coefficients of Common Metals

Let’s examine the coefficients of linear expansion for some widely used metals: steel, aluminum, copper, and iron. These materials form the backbone of countless structures and devices, making their thermal behavior a critical consideration.

-

Steel: Steel typically exhibits a relatively low coefficient of linear expansion, generally around 12 x 10-6 /°C. This makes it a dimensionally stable choice for structures where minimal expansion is desired.

-

Aluminum: Aluminum, in contrast, boasts a significantly higher coefficient, approximately 23 x 10-6 /°C. This greater expansion can be beneficial in some applications, but also requires careful management in designs.

-

Copper: Copper falls somewhere in between, with a coefficient around 17 x 10-6 /°C. Its good thermal conductivity coupled with moderate expansion makes it suitable for heat transfer applications.

-

Iron: The coefficient of linear expansion for iron is very similar to steel, around 11.8 x 10-6 /°C. The similarities between the two are due to steel consisting of iron with small amounts of other elements added.

The significant differences among these metals highlight the importance of selecting the right material for a given task. For instance, using aluminum alongside steel in a structure without accounting for their differing expansion rates could lead to stress and potential failure.

Metal Selection Based on Expansion Properties

The choice of metal in a specific application often hinges on its expansion properties. Here are a few examples:

-

High-Precision Instruments: In instruments requiring extreme accuracy and dimensional stability, such as precision measuring devices, materials with very low expansion coefficients are essential. Specialized alloys like Invar (containing iron and nickel) are frequently used because of their exceptionally low thermal expansion.

-

Overhead Power Lines: The coefficient of thermal expansion is considered when designing overhead power lines. Conductors that are suspended between poles will expand and contract with changes in temperature.

-

Heat Exchangers: In heat exchangers, copper is often preferred due to its excellent thermal conductivity and moderate expansion. These are critical characteristics for efficient heat transfer. The tubes in heat exchangers can expand under temperature changes, requiring designs that accommodate this movement.

-

Bridges and Buildings: Steel’s relative low coefficient of expansion makes it desirable for construction. However, expansion joints are still critical to incorporate into the structure to accommodate thermal changes.

The key is to match the material’s properties to the demands of the application, minimizing potential problems caused by thermal expansion.

The Role of Alloy Composition

It’s important to note that the composition of an alloy can significantly influence its linear expansion. By carefully combining different metals, engineers can tailor the expansion properties of the resulting alloy to meet specific requirements.

For example, adding nickel to iron creates Invar, an alloy with an exceptionally low coefficient of linear expansion. Similarly, the addition of other elements to steel can modify its expansion behavior, making it suitable for a wider range of applications. This ability to fine-tune material properties through alloying is a powerful tool in engineering design. Careful consideration of alloy composition is a major part of creating high-performing, durable, and safe solutions.

Having established that a material’s coefficient dictates its expansion behavior with changing temperature, it’s natural to question how this plays out in the real world. Different metals, with their varying atomic structures and bonding characteristics, exhibit a wide range of expansion coefficients. This inherent diversity is not merely a scientific curiosity; it directly impacts material selection and design choices across countless engineering applications.

Engineering Applications of Linear Expansion

Linear expansion, often viewed as a theoretical concept, is a critical factor in the design and construction of various engineering marvels. Bridges, buildings, railway tracks, pipelines, and power lines all require careful consideration of thermal expansion to ensure structural integrity and operational safety. Ignoring these effects can lead to catastrophic failures, underscoring the importance of proactive engineering design.

Expansion Joints in Bridges and Buildings

Expansion joints are intentionally created gaps within a structure designed to accommodate the movement caused by thermal expansion and contraction. They represent a crucial adaptation to the natural behavior of materials in response to temperature fluctuations.

The Necessity of Expansion Joints

The need for expansion joints arises from the inherent properties of construction materials, primarily concrete and steel, which expand and contract with temperature changes. Without these joints, the stress generated by constrained expansion can exceed the material’s tensile strength, leading to cracking, buckling, or even structural collapse.

Expansion joints essentially act as stress relievers, allowing sections of a structure to move independently. This movement prevents the build-up of internal forces that could compromise the overall integrity of the structure. Their presence is a testament to the understanding and management of material behavior under varying environmental conditions.

Examples of Expansion Joint Designs

Expansion joint designs vary depending on the specific application and the expected range of movement. In bridges, common designs include finger joints, which interlock like fingers, and modular expansion joints, which consist of multiple parallel beams that slide relative to each other. These designs are engineered to handle significant loads and large movements while maintaining a smooth riding surface.

In buildings, expansion joints often appear as simple gaps filled with flexible sealant. These joints may be visible on the exterior of the building or concealed within the structure. Larger buildings, particularly those with extensive horizontal spans, require more complex expansion joint systems to accommodate the cumulative effect of thermal expansion.

The design and implementation of expansion joints involve a careful balance between structural requirements and aesthetic considerations. Effective expansion joint design ensures long-term durability and safety without compromising the visual appeal of the structure.

Linear Expansion in Railway Track Design

The design of railway tracks also incorporates considerations for linear expansion, particularly in regions with significant temperature variations. Steel rails expand in hot weather and contract in cold weather. If this expansion and contraction are not properly managed, it can lead to track buckling (sun kinks) or rail fractures, both of which pose serious safety hazards.

To accommodate thermal expansion, railway tracks are typically laid with a small amount of slack. The rails are not rigidly fixed along their entire length, allowing them to expand and contract freely. In some cases, expansion joints are also incorporated into the track design.

Another technique involves stressing the rails during installation. This involves stretching the rails to a specific tension at a moderate temperature. When the temperature rises, the expansion is offset by the pre-tension, reducing the risk of buckling. Conversely, when the temperature drops, the tension increases, but the rails are designed to withstand the increased stress.

Pipelines and Power Lines: Managing Thermal Expansion

Pipelines and power lines, which often span long distances, are also susceptible to thermal expansion. In pipelines, expansion loops or bends are incorporated into the design to absorb the expansion and contraction. These loops provide flexibility and prevent the build-up of excessive stress in the pipe.

For above-ground pipelines, expansion loops are visually prominent features. Underground pipelines may utilize buried expansion joints or be snaked within the trench to provide the necessary flexibility.

Power lines, suspended between towers, utilize the sag in the cables to accommodate thermal expansion. The sag increases in hot weather as the cables expand and decreases in cold weather as the cables contract. Engineers carefully calculate the sag to ensure that the cables maintain adequate clearance from the ground and other obstacles under all temperature conditions.

The design of pipelines and power lines requires a thorough understanding of material properties, environmental conditions, and structural mechanics. Effective management of thermal expansion ensures the safe and reliable operation of these critical infrastructure systems.

Having highlighted the critical role expansion joints play in large-scale infrastructure, it’s fascinating to observe how this principle is also ingeniously applied at a much smaller scale. One of the most compelling demonstrations of harnessing differential linear expansion lies in the functionality of bimetallic strips.

The Role of Bimetallic Strips

Bimetallic strips offer a tangible illustration of how differing linear expansion coefficients can be exploited for practical purposes.

These strips, a clever fusion of two distinct metals, are central to various temperature-sensitive devices, bridging the gap between theoretical understanding and everyday applications.

Construction and Function

A bimetallic strip, at its core, is a composite material. It is usually created by bonding two different metals with dissimilar coefficients of thermal expansion.

Common pairings include brass and steel or copper and aluminum.

The bonding process, often achieved through riveting, welding, or brazing, ensures intimate contact between the two metals along their entire length.

This intimate connection is critical for the strip’s functionality.

When subjected to a temperature change, each metal attempts to expand or contract according to its inherent coefficient of linear expansion.

The Bending Phenomenon: Exploiting Differential Expansion

Because the metals are bonded, they cannot freely expand or contract independently.

The metal with the higher coefficient will attempt to expand more than the metal with the lower coefficient. This disparity creates internal stresses within the strip.

The result is a bending or curving of the strip.

The direction of the bend is predictable: the strip will curve towards the side with the lower expansion coefficient. This bending action is directly proportional to the temperature change.

The greater the temperature difference, the more pronounced the bending.

Applications Across Industries

The bending behavior of bimetallic strips, precisely linked to temperature changes, makes them exceptionally useful in a diverse range of applications.

Thermostats

One of the most well-known applications is in thermostats, used in homes, offices, and industrial settings to regulate temperature.

In a thermostat, the bimetallic strip is connected to a mechanical linkage that controls a switch.

As the temperature changes, the strip bends, either closing or opening the electrical circuit.

This action turns the heating or cooling system on or off, maintaining the desired temperature.

Circuit Breakers

Bimetallic strips also play a critical role in circuit breakers, protecting electrical circuits from overcurrents.

In this application, the strip is positioned in the path of the electrical current.

When the current exceeds a safe level, the strip heats up due to increased resistance.

The resulting bend trips a mechanical latch, interrupting the circuit and preventing damage to equipment or potential fire hazards.

Other Applications

Beyond thermostats and circuit breakers, bimetallic strips find use in:

- Oven temperature controls: Ensuring accurate cooking temperatures.

- Automatic chokes in carburetors: Optimizing fuel-air mixture in older engines.

- Certain types of thermometers: Providing a visual indication of temperature.

The ingenious simplicity and reliability of bimetallic strips have cemented their place in numerous control and safety systems, highlighting the practical value of understanding and utilizing the principles of linear expansion.

Having witnessed linear expansion at play in monumental structures and delicate bimetallic strips alike, the quest to precisely quantify this phenomenon naturally follows. The ability to accurately measure and study linear expansion is paramount not only for scientific understanding but also for ensuring the reliability and safety of engineering designs. Let’s explore the methods and instruments that enable us to delve into the intricacies of how materials respond to temperature variations.

Measuring and Studying Linear Expansion

The study of linear expansion is crucial for various scientific and engineering applications. Accurate measurement is essential to predicting material behavior, designing robust structures, and developing innovative technologies. Several methods and instruments are available for this purpose, each with its own strengths and limitations.

The Dilatometer: A Precision Instrument

The dilatometer stands as the primary tool for precise measurements of linear expansion. These sophisticated instruments are designed to detect and quantify minute changes in length resulting from temperature variations.

There are various types of dilatometers, each suited for different materials and temperature ranges. Common types include:

- Push-rod dilatometers

- Optical dilatometers

- Interferometric dilatometers

Push-Rod Dilatometers

Push-rod dilatometers are perhaps the most widely used type. They operate by transmitting the expansion or contraction of a sample to a sensitive displacement transducer via a push-rod mechanism.

The transducer, often a Linear Variable Differential Transformer (LVDT), converts the mechanical displacement into an electrical signal, which is then processed and recorded. These dilatometers are relatively simple to operate and can provide accurate measurements over a wide temperature range.

Optical Dilatometers

Optical dilatometers employ non-contact methods to measure changes in length. These instruments use optical techniques, such as laser interferometry or digital imaging, to track the movement of markers or edges on the sample.

Because they do not physically contact the sample, optical dilatometers are particularly well-suited for measuring the expansion of delicate or easily deformed materials.

Interferometric Dilatometers

Interferometric dilatometers offer the highest levels of precision. They use the interference of light waves to measure changes in length at the nanometer scale.

These instruments are often used for research-grade measurements and for calibrating other types of dilatometers.

The Critical Role of Accurate Temperature Measurement

The accuracy of any linear expansion measurement is inextricably linked to the accuracy of the temperature measurement. Precise temperature control and monitoring are absolutely essential for obtaining reliable results.

Thermocouples and Resistance Temperature Detectors (RTDs)

Thermocouples and RTDs are commonly used to measure the temperature of the sample during dilatometry experiments. These sensors must be carefully calibrated to ensure accurate readings.

The placement of the temperature sensor is also critical. It should be positioned as close as possible to the sample to minimize temperature gradients and ensure that the measured temperature accurately reflects the sample’s temperature.

Temperature Controllers and Environmental Chambers

Sophisticated temperature controllers and environmental chambers are often used to maintain a constant temperature or to vary the temperature in a controlled manner. These systems allow researchers to study the linear expansion behavior of materials over a range of temperatures.

Supplementary Tools and Techniques

While dilatometers provide the most precise measurements, other tools and techniques can also be used to study linear expansion, particularly in educational settings or for less demanding applications.

Rulers, Calipers, and Micrometers

Simple tools like rulers, calipers, and micrometers can be used to measure the length of a sample before and after heating. Although these methods are less precise than dilatometry, they can provide a qualitative understanding of linear expansion.

Thermometers

Thermometers are, of course, essential for measuring temperature. Digital thermometers with high resolution and accuracy are preferred for most experiments.

Experimental Procedures

Careful experimental procedures are crucial for obtaining reliable results. The sample must be properly prepared and mounted in the dilatometer.

The temperature must be carefully controlled and monitored. Data must be recorded and analyzed appropriately. Error analysis is essential to determine the uncertainty in the measurements.

By employing these tools and techniques, scientists and engineers can gain a comprehensive understanding of linear expansion, enabling them to design and build safer, more efficient, and more reliable structures and devices.

So, that’s the lowdown on linear expansion of metals! Hopefully, you now have a better understanding of how metals grow and shrink with temperature. Keep this in mind, and you’ll be all set for any science class or real-world situation where metal is involved!